Introduction

Microduct conduit systems are a crucial innovation in telecommunications and power distribution. These miniature ducts, designed to house and protect optical fibers and cables, play a vital role in modern infrastructure. By streamlining cable installation and enhancing protection and maintenance, microducts support the backbone of digital and power networks. This article delves into the significance, development, and diverse applications of microduct technology, addressing its evolution, current uses, and the challenges it faces.

History and Development of Microduct Conduit Technology

Early Beginnings and Limitations

The history of conduit technology is rooted in the basic necessity to protect and manage wires and cables efficiently. Initially, early conduit systems were bulky and rigid, crafted predominantly from metal or hard plastic. These materials, while providing essential protection, limited the adaptability and practical application of the conduits. They were difficult to install in complex or tight spaces, making them less than ideal for the dynamic needs of growing urban infrastructures and expanding industrial environments.

Transition to Microduct Systems

As the needs of the telecommunications and power industries evolved, so did conduit technology. The development of microduct systems marked a significant milestone, introducing much-needed flexibility and scalability into cable management practices. Unlike their predecessors, microducts are made from lightweight, flexible materials such as high-density polyethylene (HDPE). It is allowing for easier installation and better adaptation to various environments.

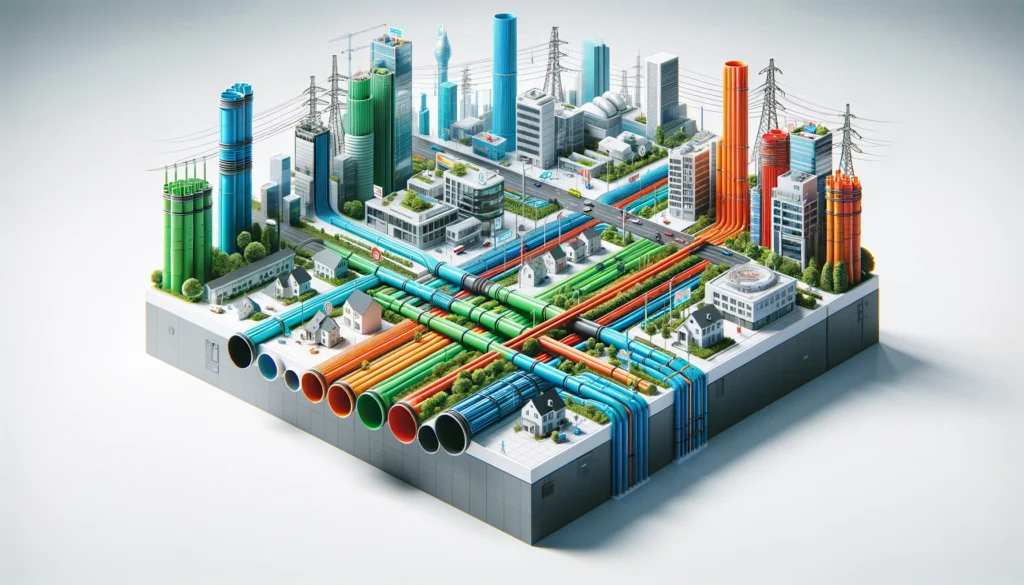

These systems were specifically designed to accommodate the rapid expansion of fiber optic networks. This is which required more sophisticated and protective conduit solutions to handle the delicate nature of fiber optic cables. The slim profile and modular design of microducts allow for multiple cables to be housed within a single conduit, maximizing space and efficiency. This is particularly beneficial in densely packed underground or enclosed routing areas, where space is at a premium.

Meeting Modern Demands

Today, microduct systems are integral in meeting the growing demands for efficient, reliable cable protection systems. They offer several advantages, including reduced installation costs, minimal physical footprint, and enhanced protection against environmental factors and physical interference. As the global demand for data and power transmission continues to escalate, the role of advanced conduit systems like microducts becomes increasingly critical, ensuring that infrastructure can keep pace with technological advancements and the exponential growth of network traffic.

Types of Microduct Conduits

Material Selection and Durability

Variety of Materials Used Microduct conduits are crafted from a range of materials, predominantly including polyethylene and other flexible, yet durable plastics. These materials are selected based on their high resistance to environmental stressors such as UV radiation, extreme temperatures, and chemical exposure. The robustness of these materials ensures that the conduits can protect enclosed cables from physical damage, such as crushing or abrasion, which is critical in both exposed and buried installations.

Advantages of Plastic Conduits The use of plastics like polyethylene in microduct conduits offers several advantages. These materials are not only lightweight and flexible but also inherently resistant to corrosion, unlike traditional metal conduits. This resistance to decay extends the lifespan of the conduit systems and reduces maintenance needs, making them more cost-effective in the long run. Additionally, the flexibility of plastic allows for microducts to be coiled and easily transported to sites, simplifying the logistics of large projects.

Customization and Versatility

Adaptability to Various Applications Microduct conduits are available in various sizes and can be customize to meet specific requirements, ranging from small diameter options suitable for residential applications to larger conduits used in industrial settings. This variability ensures that regardless of the scale or complexity of the project, there is a microduct solution available that can be tailor to fit the needs of the installation.

Integration with Existing Infrastructure One of the standout features of microduct systems is their ability to integrate seamlessly with existing infrastructure. Whether incorporate into new constructions or used in retrofitting or upgrading projects, microducts can be easily added without significant disruption to existing services. This seamless integration is facilitate by the conduits’ modular design, allowing them to be interconnect or expand upon as needed, which is particularly advantageous in evolving urban landscapes and industrial areas where future expansion is anticipated.

Installation Techniques

Pre-Installation Considerations

Route Planning and Soil Analysis Before the actual installation of microduct conduits, careful planning is essential to ensure the success and efficiency of the project. This preliminary phase includes detailed route planning. It is where the path of the conduit is mapped out to avoid existing utilities and optimize the installation process. Soil analysis is also critical, as it determines the appropriate installation techniques by assessing soil type, stability, and the presence of groundwater. These factors can significantly affect the choice of microduct materials and the installation method.

Understanding Local Regulations Another vital pre-installation step is understanding and adhering to local regulations. This includes obtaining necessary permits and ensuring that the installation complies with local, state, and federal standards. It is which may dictate aspects of the project such as depth of burial, types of environments where installation can occur, and safety measures to be followed during the process.

Installation Process and Techniques

Trenchless Technology and Conduit Laying The installation process for microduct conduits is methodical and often utilizes trenchless technology to minimize disruption to the surrounding area. Trenchless methods such as horizontal directional drilling (HDD) or microtunneling allow for the conduit to be installed under landscapes, roadways, or existing structures without the need for extensive excavation. This technique not only reduces the environmental impact but also decreases the installation time and costs.

Threading Microducts and Sealing Connections After laying the conduit, the microducts are thread through these channels. Precision in threading is crucial to prevent damage to the ducts and the cables they will house. Once the microducts are in place, connections are meticulously seal to ensure the integrity of the protective environment. Sealing is vital to protect the cables from moisture, dirt, and other contaminants that could compromise the system.

Benefits of Using Microduct Conduits

Enhanced Durability and Protection

Superior Durability and Robust Protection Microduct conduits are renown for their exceptional durability and robustness. This is which are crucial in safeguarding sensitive fiber optic cables. These conduits are specifically design to withstand environmental and mechanical stresses. It is such as temperature fluctuations, moisture, chemical exposure, and physical impacts. The protective environment they provide significantly reduces the risk of cable damage. It is which is essential for maintaining the integrity and performance of telecommunications and power networks.

Environmental Resistance The materials used in microduct conduits, such as high-density polyethylene (HDPE), offer excellent resistance to adverse environmental conditions. This resistance extends the lifespan of both the conduit and the cables it houses, ensuring continuous and reliable service without frequent need for repairs or replacements. This level of protection is particularly important in harsh or fluctuating environments, where traditional conduit materials might fail.

Economic and Operational Advantages

Cost-Effectiveness Economically, microduct systems provide a significant advantage over traditional conduit systems. They require less material and labor for installation, which not only reduces initial costs but also accelerates project timelines. The simplicity and speed of installing microduct conduits. It is especially using trenchless technology, contribute to substantial savings in both time and money.

Modular Design and Maintenance The modular design of microduct systems greatly enhances their flexibility and ease of use. This modularity allows for easy expansion and adaptation of the network, accommodating future developments without extensive overhauls. Additionally, the ease of maintenance associated with microduct conduits further reduces long-term operational costs. Their design simplifies the process of adding, removing, or replacing cables, thereby minimizing disruptions and maintenance time.

Common Applications of Microduct Conduits

Central Role in Telecommunications

Housing Fiber Optic Cables for High-Speed Transmission Microduct conduits are extensively utilize within the telecommunications industry. It is primarily to house fiber optic cables. These conduits are essential for ensuring high-speed data transmission across vast networks. It is crucial for maintaining the connectivity demands of modern society. By protecting the delicate fiber optic cables from physical and environmental harm, microducts help to ensure uninterrupted service and optimal performance of communication networks.

Adaptability to Network Expansion The telecommunications sector is characterize by rapid growth and the need for scalable infrastructure solutions. Microduct systems are design to be highly flexible, allowing for the addition of new cables as network requirements expand. This scalability is particularly advantageous in the fast-evolving telecom industry. It is where adapting to new technologies and increasing demand for bandwidth is a constant challenge.

Utility and Critical Service Protection

Safeguarding Power Cables and Services In the utility sector, microduct conduits serve a critical role in protecting power cables and other essential services. These conduits shield electrical cables from environmental threats and mechanical damage. It is thus ensuring the reliability and safety of power distribution systems. This protection is vital for minimizing downtime and service interruptions, which can have significant economic and safety implications.

Versatility Across Settings Microduct systems are remarkably versatile, suitable for deployment in both urban and rural environments. Their design allows them to adapt to a wide range of environmental conditions and project scales. This is from small community projects to large-scale industrial applications. This versatility ensures that microduct conduits can be effectively integrate into diverse settings. It is providing reliable and efficient infrastructure support regardless of location.

FAQs

- What is the lifespan of microduct conduits? A: Microduct conduits typically have a lifespan exceeding 50 years, depending on the material and environmental conditions.

- How do microduct conduits compare with traditional conduit systems? A: Microduct systems offer greater flexibility, easier installation, and better scalability compared to traditional conduits, making them ideal for modern infrastructure needs.