Introduction

In the telecommunications and data transmission sectors, fiber optic cabling is known for its high efficiency and capacity. These cables, made of delicate strands of glass or plastic fibers, face risks from physical, environmental, and mechanical stresses. Acting as protective conduits, these innerducts not only secure the cables but also support organized and efficient installations. Our discussion focuses on fiber innerducts, covering their varieties, advantages, installation recommendations, and upkeep routines. By doing so, we aim to provide a comprehensive understanding of their essential role in the fiber optic infrastructure. This knowledge is crucial for anyone with involvement in the planning, installation, or management of fiber optic systems.

What is Fiber Innerduct?

Fiber innerduct is an essential conduit system that is made for this craft to encase and shield fiber optic cables. It plays a critical role in averting potential harm caused by crushing, bending, or exposure to environmental elements. Made from High-Density Polyethylene (HDPE) and Polyvinyl Chloride (PVC), fiber innerducts are met with environmental conditions and installation requirements. HDPE innerducts stand out for their robustness, adaptability, and environmental resistance, which make them perfect for outdoor cable installations. Conversely, PVC innerducts are in favor for indoor use, thanks to their fire-resistant characteristics.

The utility of fiber innerducts goes beyond just safeguarding cables; they significantly improve cable management as well. These conduits allow for the orderly segregation of cables, enabling technicians to easily organize and pinpoint cable pathways. This organization simplifies both maintenance tasks and future network expansions. Furthermore, innerducts enhance the efficiency of installations by ensuring smoother cable deployments. This will be minimizing the chances of cable damage during the process.

Incorporating fiber innerducts into cable installations provides multiple benefits, from improved safety to better organization. Their selection depends on the specific needs of the installation environment. By choosing the appropriate type of innerduct, technicians can ensure not only the longevity and reliability of fiber optic networks. This adaptability and protection are vital for maintaining the integrity of high-speed data transmission networks.

Benefits of Using Fiber Innerducts

The integration of fiber innerducts into fiber optic cabling systems brings several benefits. These conduits primarily offer strong protection against physical damage, effectively guarding the cables from impacts, cuts, and environmental threats. Such safeguarding is vital for prolonging the lifespan of fiber optic cables and maintaining uninterrupted signal quality.

Enhancing Cable Management

Moreover, fiber innerducts greatly enhance cable management. They facilitate a tidier and more manageable cable configuration, critical for streamlined system upkeep and fault finding. The methodical identification and separation of cables diminish the chances of unintentional harm during maintenance of other infrastructure components.

Installation Efficiency

A further advantage is the boost to installation efficiency that fiber innerducts provide. Conduits that come pre-equipped with pulling tape simplify the cable laying process. This feature allows for smoother and less hazardous cable installations, reducing the likelihood of cable damage and the subsequent expenses for repair or replacement. Furthermore, the adoption of innerducts supports future network expansion. It permits the introduction of more cables through existing conduits, enabling system growth without the necessity for a comprehensive infrastructure redo.

Installation and Maintenance

Employing fiber innerducts not only secures the physical integrity of fiber optic cables but also optimizes the installation and maintenance processes. Their use ensures an organized, accessible, and scalable network infrastructure. This scalability is especially important in today’s rapidly evolving technology landscape, where the ability to adapt and expand is crucial. By leveraging the protective and organizational capabilities of fiber innerducts, network administrators can ensure the long-term reliability and efficiency of their fiber optic systems, readying them for future demands and technological advancements.

Installation Guidelines for Fiber Innerducts

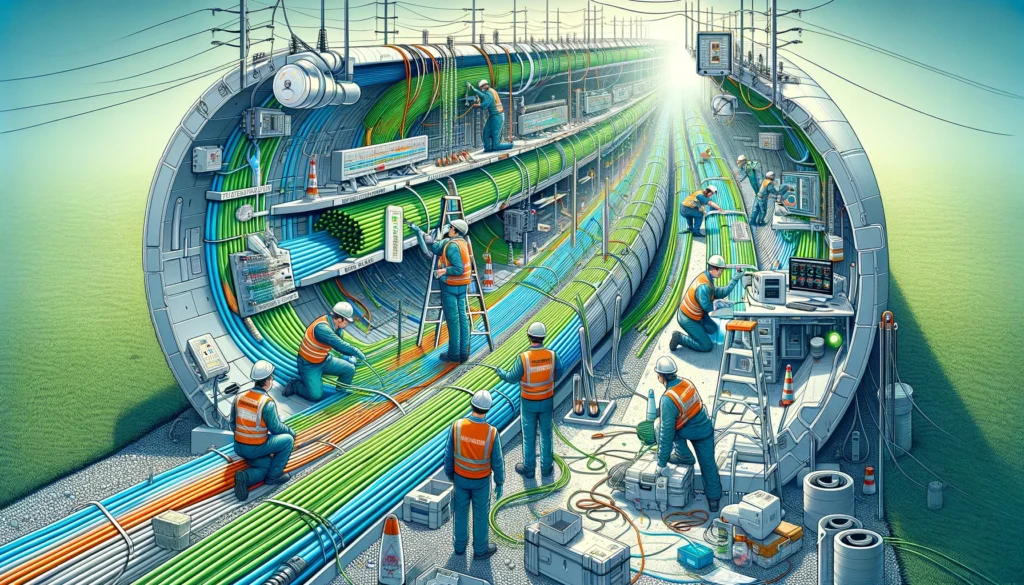

Achieving a successful fiber innerduct installation demands meticulous planning and strict adherence to established best practices. The process begins with the creation of an in-depth installation blueprint. This blueprint should detail the proposing of the path, the type of innerduct to be used, and the specific methodologies for installation. It’s important for this plan to take into account the prevailing environmental conditions, any potential impediments, and considerations for future network expansions.

Maximum Pulling Load

A key principle during the installation of fiber innerducts is to never surpass the cable’s maximum pulling load. The application of appropriate lubricants can significantly decrease friction, enhancing the installation process. For installations covering extended distances, initiating the pull from the central point outward to both ends is to advise for evenly distribute tension, thereby minimizing the risk of damage.

Handling Cables

It’s critical to roll the cable off its spool rather than spinning it, to avoid twisting and exerting undue stress on the fibers. In indoor settings, the utilization of innerducts not only offers additional protection to the cables but also facilitates superior cable management. It’s imperative to pull the cables through the innerduct rather than pushing them to prevent any breach of the cable’s bend radius. This in which could lead to fiber damage.

Monitoring and Reliable Crew

Continuous monitoring of the supply reel and effective communication across the installation path are indispensable for averting complications such as cable kinks or entanglements. Ensuring a minimum crew is on hand is essential for overseeing the pulling equipment, supply reel, and to coordinate the entire operation efficiently.

Specialized Equipment

Furthermore, clear markings and protective measures at crucial points along the installation route can prevent accidental damage. The use of specialized equipment, such as cable blowers for long conduit runs, can further streamline the installation while safeguarding the integrity of the fiber optic cables.

In summary, the installation of fiber innerducts is a complex procedure that requires careful planning, precise execution, and continuous oversight. By following these guidelines, technicians can ensure the installation is performed efficiently, reducing the risk of damage and future complications. Not only it preserves the integrity of the fiber optic cables but also lays a strong foundation for a reliable infrastructure.

Maintenance and Troubleshooting

Ensuring the longevity and reliability of fiber innerduct systems necessitates consistent maintenance and prompt troubleshooting. It’s imperative to carry out regular checks to spot and remedy any wear, damage, or obstructions in the innerducts. Keeping these conduits clean and devoid of debris is crucial for safeguarding the cables and facilitating easy access for any necessary maintenance or updates.

Addressing issues within fiber innerducts typically involves resolving problems like bends that exceed the advised radius, crushed or impaired sections of the innerduct, or complications with cable splices. The deployment of fiber optic testing tools, notably OTDRs (Optical Time-Domain Reflectometers), is instrumental in identifying the exact location and specifics of any faults in the cabling infrastructure.

By maintaining a clear and unobstructed pathway within the innerducts, the risk of cable damage is significantly reduced. This proactive approach not only aids in the preservation of signal quality but also minimizes the need for extensive repairs or replacements. Regularly scheduled inspections and the strategic use of advanced testing equipment are essential strategies in mitigating issues before they escalate, ensuring the fiber innerduct system remains robust and efficient.

FAQs on Fiber Innerducts

- What is the difference between innerduct and conduit? A: While both innerduct and conduit serve to protect cables, innerducts are specifically for fiber optic cables, offering features tailoring to their protection and organization. Conduits are broader in application and can house various types of cables.

- Can fiber innerduct be used outdoors? A: Yes, certain types of fiber innerducts, such as HDPE innerducts, are for designing of outdoor use, offering resistance to UV exposure, temperature fluctuations, and moisture.

- How do you size fiber innerduct for a project? A: Sizing fiber innerduct involves considering the number and type of cables to be in house, the potential for future expansion, and the installation environment. It’s crucial to ensure enough space for cable pulls and bends without exceeding the cable’s bend radius or fill capacity of the innerduct.

This comprehensive guide to fiber innerducts underscores their indispensable role in protecting and managing fiber optic cabling systems. By adhering to the outline of installation guidelines and maintenance practices, the integrity and performance of fiber optic networks will be preserve, ensuring reliable data transmission for years to come.